In a MicroSD failure, the card’s file allocation table is violated. The first thing a user may encounter is a decision – to try to reanimate the structure of the file system or copy what you need to a computer and then format the drive. Keeping up with a number of rules will help simplify the subsequent recovery of files from MicroSD.

To reduce the risk of complete loss of information on the card, the user must consider two main points:

- During the check of the drive, it must not be pulled out of the reader.

- Third-party applications, in case of improper use, can cause harm. It is better to give the card to specialists.

The computer or mobile gadget where the problem occurred can additionally damage the files. It is almost not possible to determine the actual cause of the failure at home. Most often, the user has only one option of the opportunity to save archives. It is to entrust their media storage to a reliable data recovery company.

MicroSD Data Recovery Case

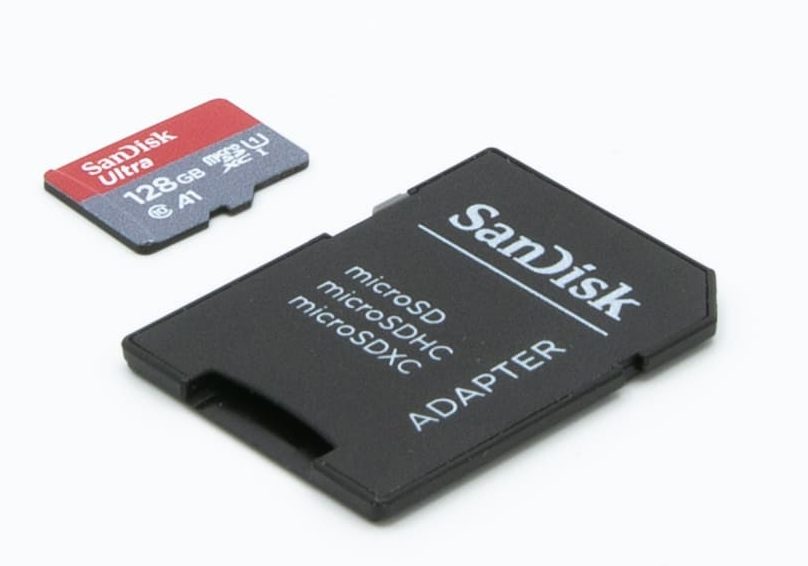

PITS Global Data Recovery Services provides professional file restoration from failed MicroSD memory cards. Recently, we received a request for a technical inspection of the SanDisk MicroSD card. As soon as we received the device, we started its evaluation. Our engineers were thoroughly examining it and estimating its condition and chances for successful recovery.

A monolithic microSD card with its protective plastic layer was removed. After checking the external condition of the drive, we decided to work on the pinout map. The pinout map has been inspected, and it looked promising for further action. A pinout is a reference to the pins or pins that connect an electrical device or connector. It describes the functions of the transmitted signals and the circuit input/output (I/O) requirements. Each individual pin in a chip, connector, or individual wire is defined as text, a table, or a diagram.

MicroSD Data Recovery

The main challenge, in this case, was to ensure successful data recovery was possible. After discussing all recovery details and service options with the client, we received approval for continuing.

If errors are detected, an attempt is made to read the surviving data from the MicroSD. It should be noted that a simple algorithm was used here.

And in this way, it was possible to save only information that turned out to be inaccessible due to the loss of the “path” to it. We would have to use specialized recovery equipment when faced with sector damage and the failure of part of the service data.

Some of the file and folder names may be corrupted during data extraction. It is more critical that their structure is preserved so that no errors appear when viewing is started. PITS Global Data Recovery Services’ engineers handle file structure corruption recovery as well.

Our data recovery experts also used precise tools, as their goal was to achieve the maximum recovery results without damaging the card. As a result, we successfully handled all the difficulties and restored lost files.

Our advanced recovery tools and the experience of our engineers help PITS Global Data Recovery Services keep its 99% success rate. Call our customer services at (888) 611-0737 to request our advanced data recovery solutions. Or fill in a request form, and we will reach out to you in no time.